What is MRO (Maintenance, Repair and Operations)?

MRO refers to the activities involved in the maintenance, repair, and upkeep of physical assets, machinery, equipment, and infrastructure necessary for the day-to-day operations of an organization.

MRO encompasses a wide range of tasks and processes aimed at ensuring the proper functioning and longevity of assets, as well as minimizing downtime and optimizing operational efficiency. This includes routine maintenance, inspections, repairs, spare parts management, inventory control, and facility management.

Efficient MRO management is critical for industries such as manufacturing, utilities, transportation, and facilities management, where downtime due to equipment failure can lead to significant production losses or service disruptions. Many organizations invest in MRO software and systems to streamline maintenance processes, track asset performance, manage inventory, and schedule maintenance activities effectively.

OpenTeQ provides comprehensive support for the development and implementation of NetSuite for MRO companies. Reach out to us today to learn how we can help you.

NetSuite Features that supports

Maintenance, Repair, and Operations (MRO)

NetSuite can be a valuable tool for MRO, providing them with the necessary capabilities to manage their complex business processes efficiently. Here's how NetSuite can benefit MRO companies.

Inventory Management

NetSuite offers robust inventory management features that allow businesses to efficiently track MRO inventory levels, monitor stock levels, and automate reordering processes. This ensures that necessary MRO supplies are always available when needed, minimizing downtime.

Procurement

NetSuite's procurement module enables businesses to streamline the purchasing process for MRO supplies. It allows for centralized procurement, automated purchasing workflows, and vendor management, helping organizations procure the right parts and supplies at the best prices.

Work Order Management

NetSuite's work order management capabilities help organizations effectively plan, schedule, and track maintenance activities. Users can create work orders, assign tasks to technicians, track labour and material costs, and monitor the progress of maintenance tasks in real-time.

Asset Management

NetSuite allows businesses to track and manage their MRO assets throughout their lifecycle. This includes recording asset details, tracking maintenance history, scheduling preventive maintenance, and optimizing asset utilization.

Financial Management

NetSuite's financial management module provides comprehensive accounting and financial reporting capabilities. Organizations can track MRO-related expenses, allocate costs to specific projects or departments, and generate financial reports to analyse MRO spending and performance.

Integration Capabilities

NetSuite offers robust integration capabilities, allowing businesses to integrate MRO management with other systems such as enterprise resource planning (ERP), customer relationship management (CRM), and manufacturing systems. This ensures seamless data flow and eliminates silos between different departments.

Customization and Scalability

NetSuite is highly customizable and scalable, allowing businesses to tailor the system to their specific MRO management needs and accommodate growth over time. Custom workflows, fields, and dashboards can be configured to meet unique requirements.

Maintenance Scheduling

NetSuite's maintenance scheduling capabilities help MRO service providers plan and execute maintenance tasks efficiently. It optimizes the scheduling of preventive and predictive maintenance, ensuring that equipment and assets are well-maintained, and critical operations remain uninterrupted.

Functionality and Automations Included in Scope:

Improve your NetSuite capabilities by adding OpenTeQ MRO module functionalities:

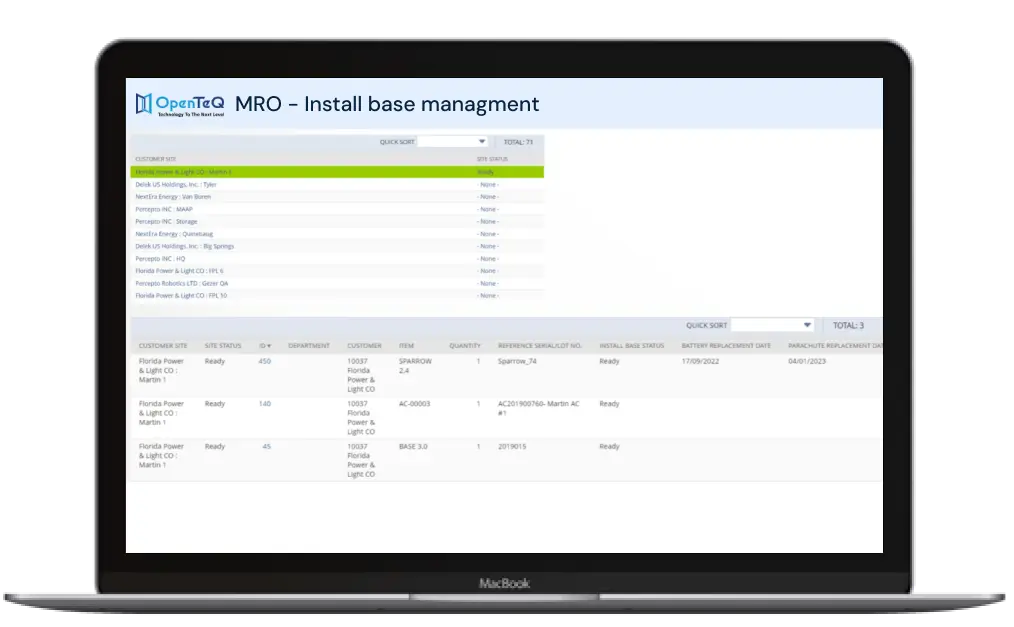

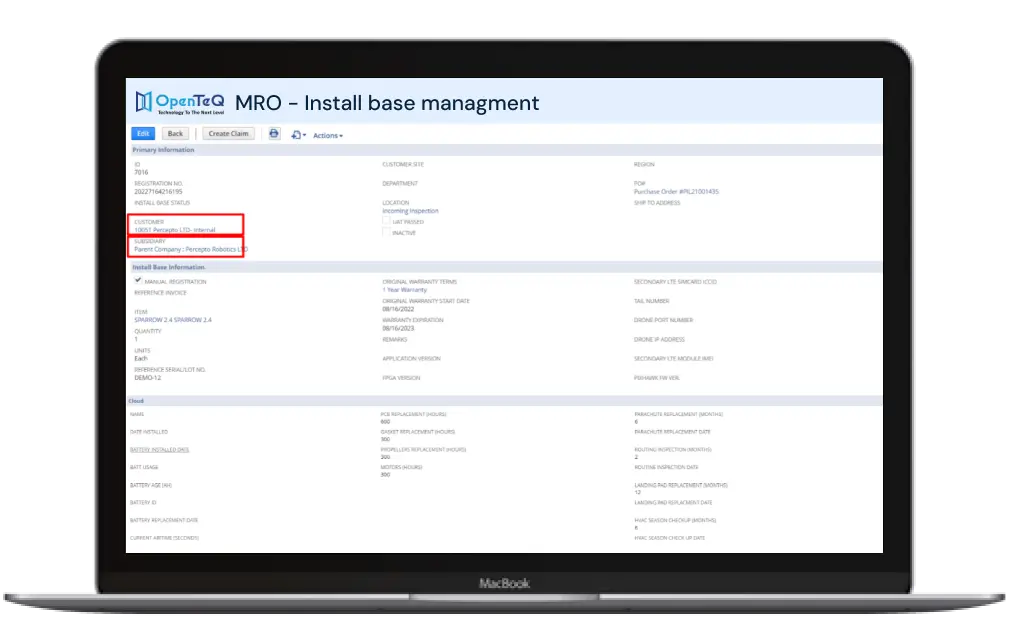

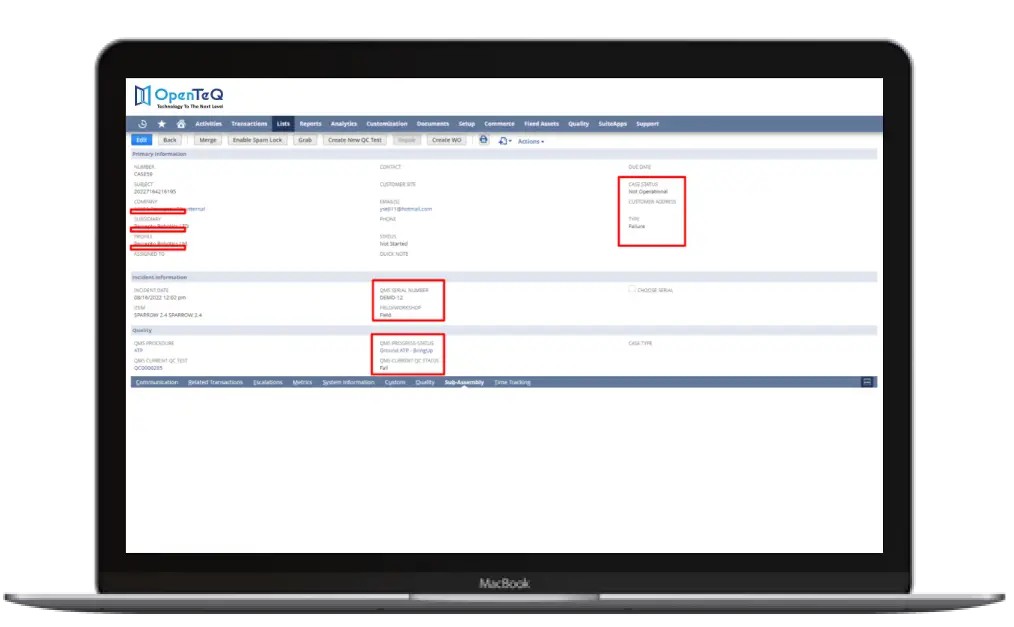

- Install base management through product full lifecycle, including status management based on preventive actions. Includes ssystem information and sub assemblies' information.

- Auto creation of fixes asset, by NetSuite FAM module, based on sale order types.

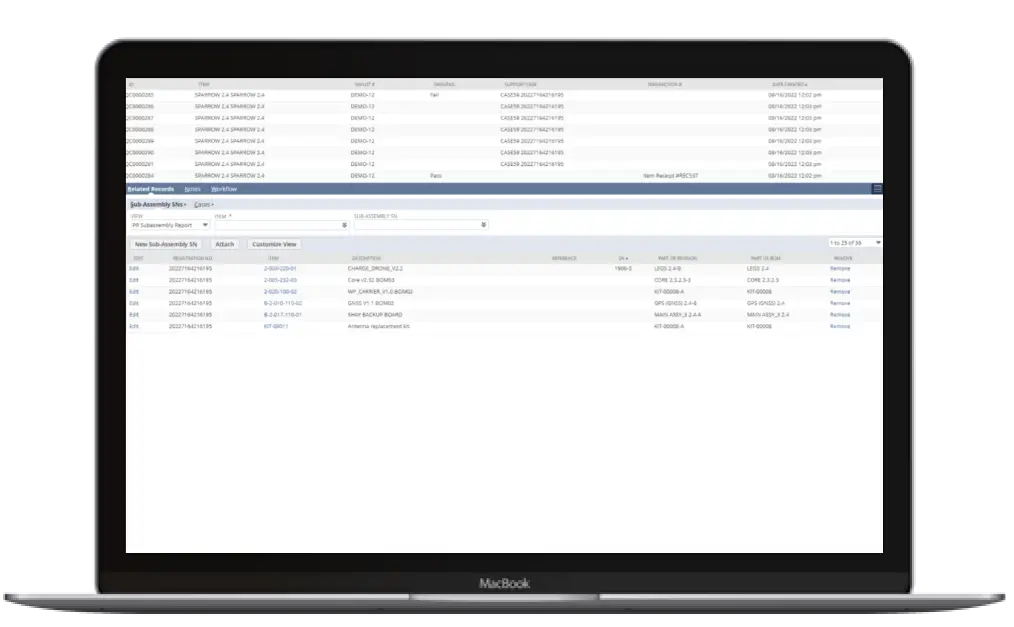

- Traceability of all transactions relevant to the specific product, including production, testing, rework, and subassemblies traceability.

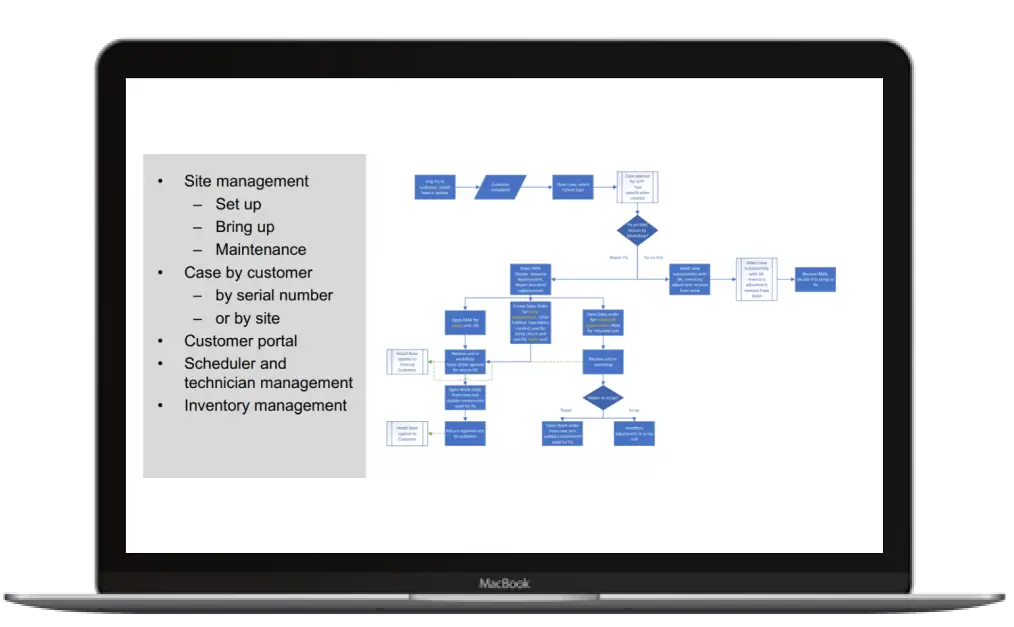

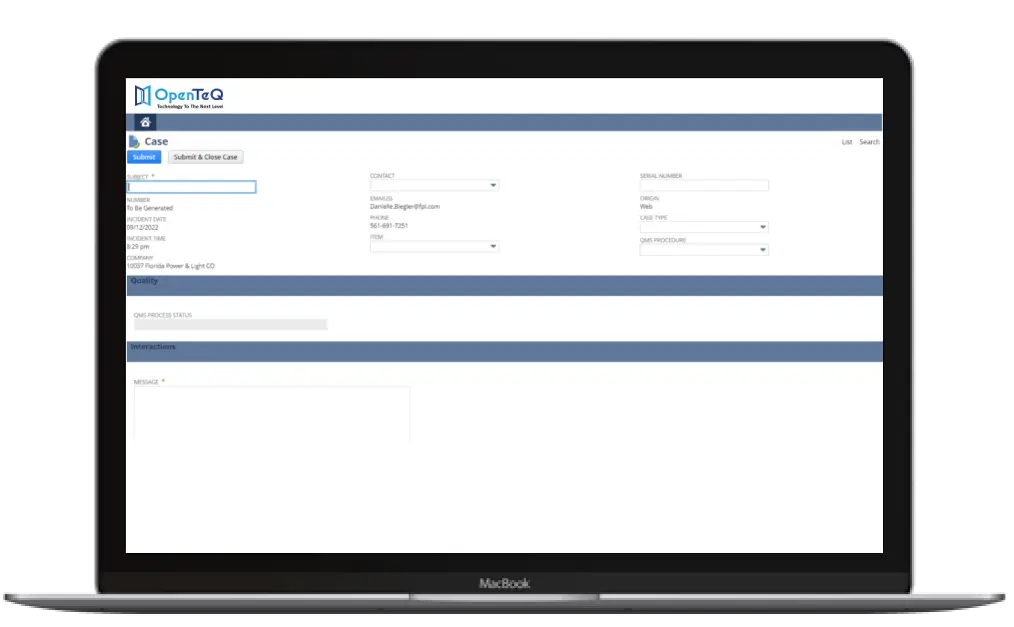

- Manage service calls and technician’s field system, based on Top+ advanced NetSuite Case management with

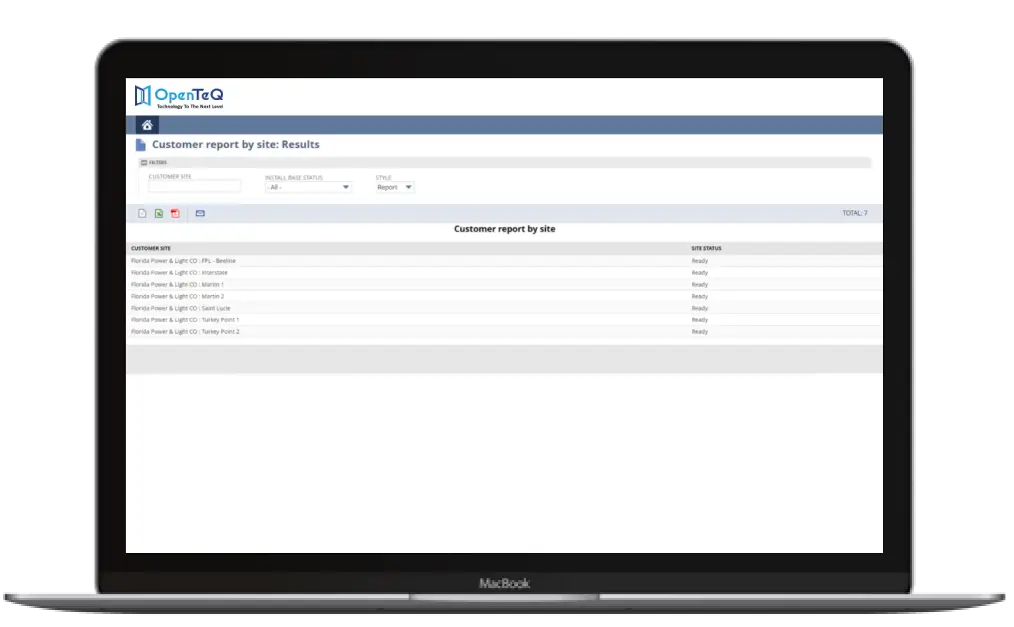

- Facility management – install base status, repair, and P&L.

- Scheduler and technician management for field support, including maintenance book/check list, field replacement and toolbox inventory management for the technician, including support for serial device management, Spare parts report for reading and immediate inventory update, working hours report, Fault reports, damage photos, management of customer questionnaires, Carrying out stock transfers between technicians in the field, goods receipts directly to the technician's toolbox.

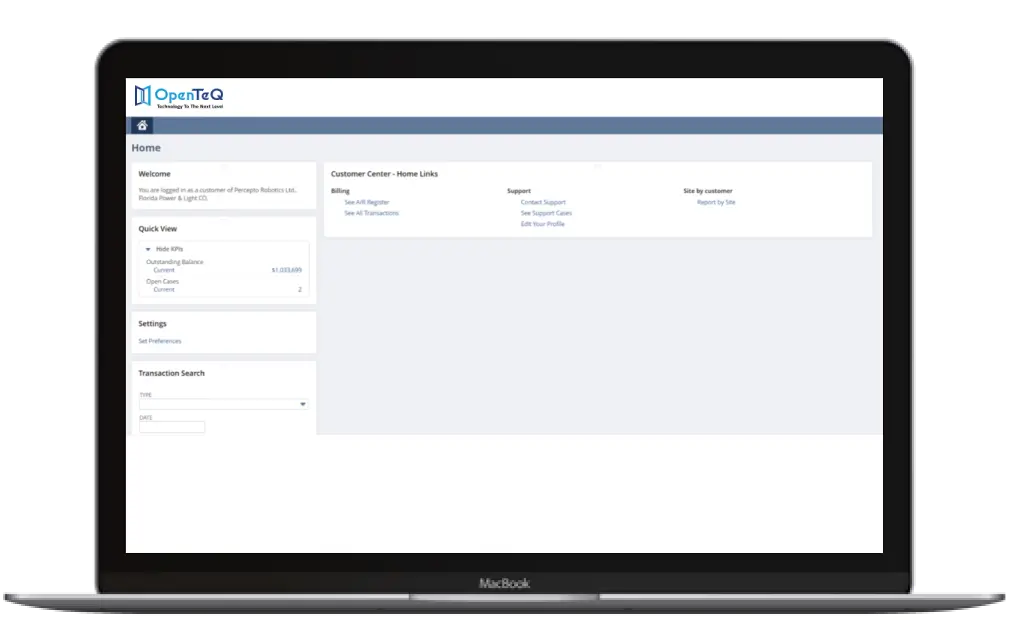

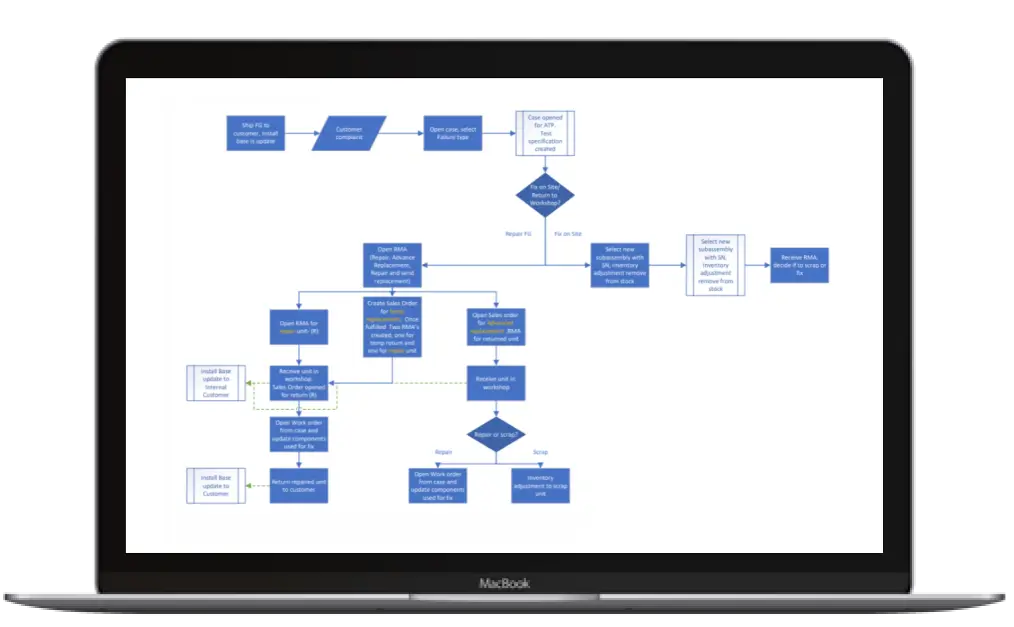

Maintenance Repair & Operations (MRO) – Case Management

Solution Screenshots

Frequently Asked Questions

Maintenance, repair and operations (MRO) refers to a range of activities that keep a company running on a day- to-day basis. Companies rely on their supply chains to provide the materials, tools and components they need for MRO activities. The items that each company stores for this purpose are known as MRO inventory.

MRO inventory includes consumables, tools and spare parts. Examples include janitorial supplies, safety equipment, maintenance and repair supplies, technology, office supplies and laboratory equipment.

Without MRO inventory, manufacturers would not be able to operate. Companies depend on having items as varied as replacement parts, janitorial supplies and office supplies on hand so their daily activities can continue uninterrupted.

MRO inventory comprises the consumable materials, equipment and supplies needed for maintenance, repair and operations activities. MRO includes items that are used in a production process but unlike raw materials — are not incorporated into a company's finished products. Spare parts and tools for repairing manufacturing equipment are MRO inventory items, as are gloves and goggles used by plant workers. MRO inventory affects the productivity of virtually every department, so it's vital to maintain enough MRO inventory to keep the business running while also not overstocking.

MRO Inventory Examples

MRO inventory includes a very wide range of equipment and supplies. Examples include:

- Maintenance and repair supplies for production machinery: Machine oil and other lubricants, light bulbs, valves, bearings, cutting fluid and spare parts, such as motors and gears.

- Safety equipment: Masks, ear plugs, hard hats, respirators and face shields.

- Janitorial supplies: Disinfecting and cleaning sprays, liquids and powders, mops, buckets, brooms, rags and dust cloths and disposable gloves.

- Office supplies: Personal computers, printers and toner, furniture, paper, pens, and pencils.

- Laboratory supplies for testing or research: Beakers, syringes, test tubes and scales.